Industrial automation can be described as a discipline or as a set of technologies and functions. Its advantages, characteristics, and peculiarities, however, are many and depend to a great extent on the fields of application.

Minting and casting are two different ingots production processes in which industrial automation can bring significant advantages and invaluable automatic process control. But let's see first what their main characteristics are.

Welding is an extremely demanding process, and today industrial robotics is making daily strides in the evolution of robots that can replace humans in a complex and risky task.

Jewelry is a product that never loses appeal in the market, both for its value as a luxury good and as an investment, and as a source of gratification. The prospects for the future, even if to be remodeled compared to what was the past, are therefore there, considering the important role that the luxury sector, and therefore also the goldsmith sector, has made in the Made in Italy industry.

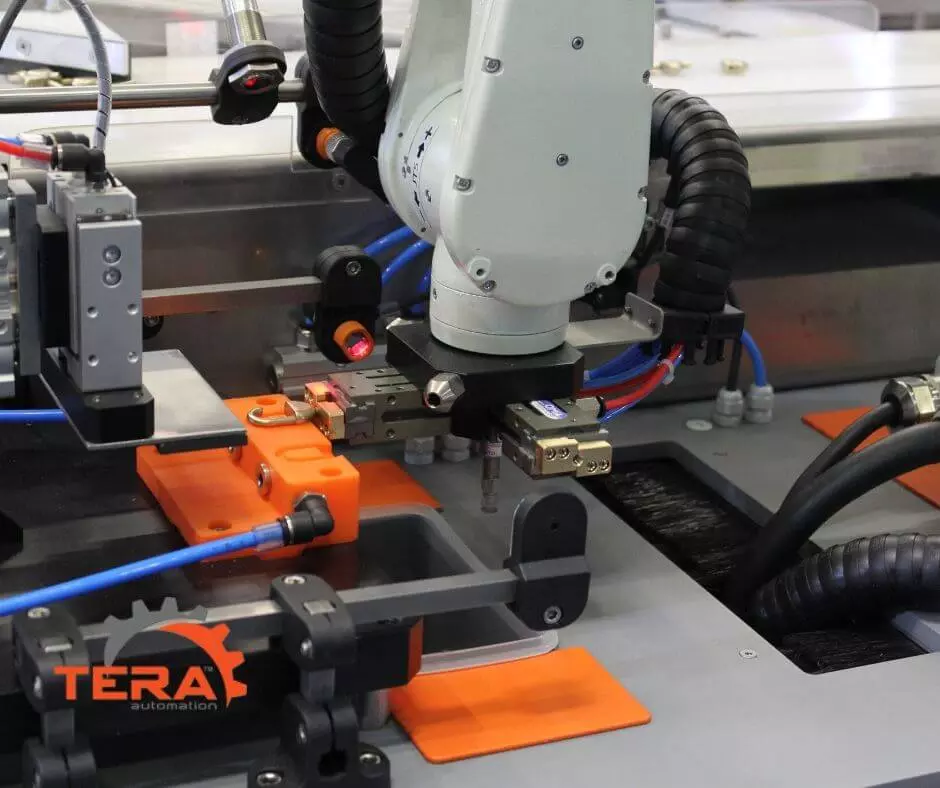

Antropomorphic robots with six degrees of freedom are the most commonly used industrial robots in industrial robotics solutions, because of their design which guarantees maximum flexibility.

Industrial robotics, born with the automotive production, found a big and positive expansion in the food industry. Food industry means both food and beverages production and today in Italy is in first place for global turnover in the manufacturing sector.

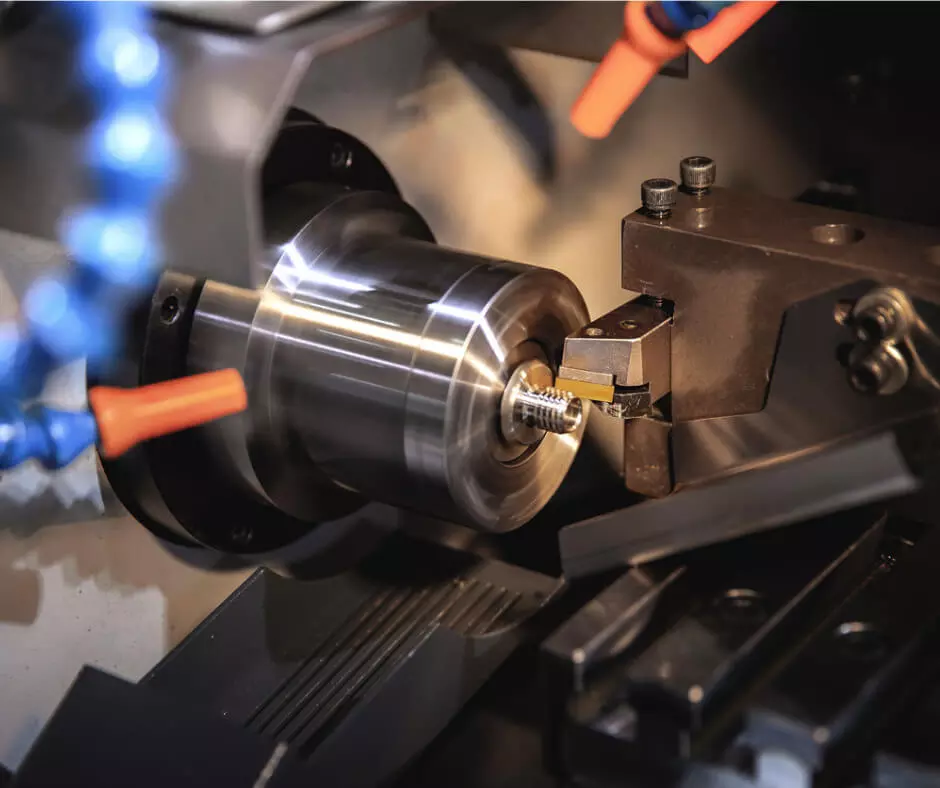

Robotic cells for CNC subservience are created with the aim of maximizing the efficiency of CNC machine tools and optimizing the production flow, thus obtaining better performances.

But what exactly do robotic cells do in this field? And how can industrial robotics help men in their tasks?

A robotic work cell is really able to take a production reality to another level. The greatest advantage of installing a robotic island in a company is certainly that of having a considerable increase in production that can be measured immediately. But how can a robotic island really revolutionize the company's production cycle? Let's see it together.

The pharmaceutical industry is the manufacturing field with the highest growth in the decade of 2008-2018 in Italy. Exports increased by 100% while production increased by 22%, as opposed to the rest of the Italian manufacturing industry which suffered a -14% decline over the same period. The data, therefore, speak clearly.

E-waste, also known as RAEE (Rifiuti di Apparecchiature Elettriche ed Elettroniche) in italian or WEEE (Waste of Electric and Electronic Equipment) in english, consists of electronic devices that must be disposed because they’re broken or no longer working.

Industrial automations for palletizing activities are useful tools for many productive sectors. But what exactly do we mean when we use the term “palletizing”? What is industrial robotics help when it comes to this type of activity?

Those who work in automation and industrial robotics known that the innovation they propose with their technologies and machinery must comply with precise safety standards. According to the “Consolidated Act on Health and Safety at Work”, indeed, Whenever the use of robots and robotic islands is foreseen in the production cycle, workplaces must comply with precise safety criteria.

When an industrial robot is programmed for a specific use and is placed in a robotic cell, it performs continuous work without interruptions, without the aid of lighting and, most importantly, without the supervision of any operator. These three details are enough material to understand right away the great advantage of industrial robotics in many fields.

The historical field of application of industrial automation is undoubtedly that of the automotive sector. Only a couple of decades passed from Henry Ford's assembly line to the first welding and painting robots, and even today the production chain of cars and motorcycles enjoys the benefits of these ingenious technological developments

When referring to industrial automation, artificial vision systems are an essential tool. But what is an artificial vision system? What advantages can it provide when installed in a robotic cell?

ISO TR/8373-2.3 norm defines industrial robot as: "automatically controlled, reprogrammable, multipurpose manipulator, programmable in three or more axes, which can be either fixed in place or mobile for use in industrial automation applications".

There are four key points that can help you understand if your company can integrate a robotic cell to improve specific production flows and increase production rates. They concern the tasks to be performed by the industrial robot located in the cell, the sector in which your company operates, the cost-benefit ratio for a ROI calculation and the type of environment in which it will be installed.

This is a key topic for many entrepreneurs who are considering strategies to innovate and improve their company's production flow. Robotized cells may look like simple machines, but they actually involve complex projects and highly advanced technical solutions, which are often tailored to make the production flow of each company smoother and more efficient.

The use of robotized cells for the tending of computer numerical control machines is a revolutionary system that has deeply affected the production potential of many Italian companies operating in the manufacturing of metal accessories for the fashion industry, i.e. accessories for clothing and/or bags/leather goods.

One of the unquestionable advantages of industrial automation is that it allows a company to be operational even in the absence of an operator. In fact the added value of automation is exactly that of being able to work without the operator's intervention,or in any case limiting the human activity to supervision. What does this mean in practical terms for a company? Continuous productivity that is not affected by holidays, weekends, night shifts and extraordinary closure periods - even long-term ones.