SOLUTIONS FOR PRECIOUS METAL GRAINS PROCESSING, FROM PRODUCTION TO PACKAGING.

Tera Automation offers a wide range of solutions for the production, transportation, dosing and packaging of precious metals grains.

Whether in your company grains are the final product or the first stage of a more complex process such as ingot production, you can rely on our machines to get integrated or stand-alone solutions.

SOLUTIONS FOR GRAINS PROCESSING

T-GRAINS

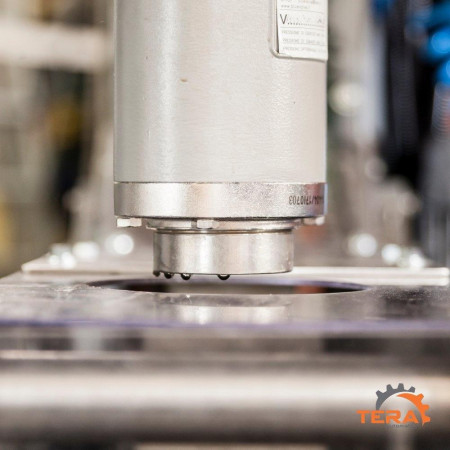

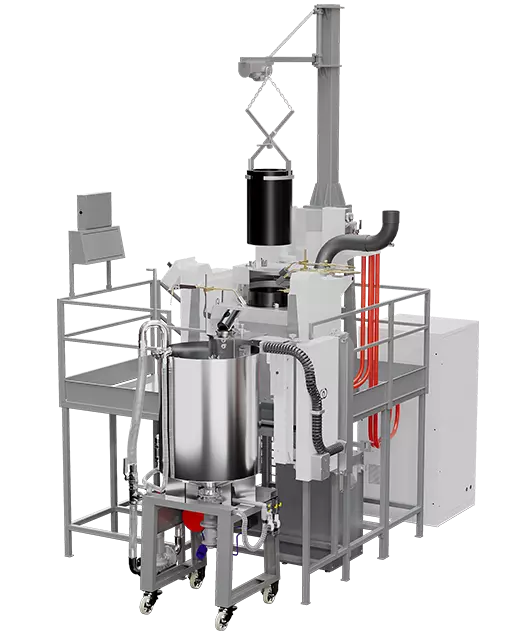

Automated grains production system

T-Grains™ is an automated system designed to produce gold and silver grains of the highest quality, eliminating the risks and slowness of manual work.

A key element of the system is the layout of the plant, which prevents the metal from cooling as it passes through the granulation tank. This is made possible by the presence of a heated casting die, equipped with a dedicated inductor. This ensures that the temperature of the molten metal remains constant, preventing production defects.

Another advantage is the minimisation of the exposure time of the molten metal to oxygen in the air, a crucial factor in achieving a perfect quality shot.

In addition, the temperature of the water in the granulating tank, which is decisive for the final quality of the grains, is controlled by a cooling system connected to a recirculation pump. This system maintains a constant water temperature in each granulation batch, ensuring uniformity in the process.

T-LIFT

Bucket conveyor belt

T-Lift™ is a vertical bucket conveyor belt with a unique shape. Thanks to the Z-shape of conveyor belts, the buckets can move in a circle in perpetual motion, exponentially increasing the speed and autonomy of metal grain batches - whether it be gold, silver, copper, brass, etc. - in any hopper type.

Thanks to its efficiency, it can be installed next to any elevated loading area, so as to fully optimize working time. Moreover, thanks to T-Lift™, tasks are safer for operators, who are not at risk of falling, and material dispersion accidents are reduced.

T-DRYRAY

Automated drying system

Metal grains must be perfectly dried to produce ingots. A one-kilogram gold ingot must be made with one kilogram of actual grains, without any moisture residues. That is why Tera Automation has developed the automated system called T-Dryray™, in which grains undergo a full drying process.

Grains are processed continuously, thus significantly optimizing the time required for this very important step.

Two units can be put in parallel to process gold and silver separately.

T-SCREENING

Vibrating screen for grains selection

T-Screening™ is a circular vibrating sieve for the selection of precious metal grains by diameter. T-Screening can be configured with various levels – 2, 3 or 4 different levels – each of which is characterized by a net with variable mesh size depending on the diameter of the grains to be separated. Each level is equipped with a special nozzle to discharge the selected grain.

T-HOPPER

Wheeled hopper

T-Hopper™ is a wheeled hopper designed for synchronized storage and transfer of precious metal grains to the T-Lift™.

T-DOSING

High-precision automatic dosing machine

T-Dosing™ is an industrial machine for the precious metals sector that automates the weighing of the granules used for the production of ingots, one of the most delicate stages of the process. The accuracy of the weight is a determining factor for investment ingots, as underweight ingots cannot be marketed, and overweight ingots would result in a clear economic loss for the producer.

T-COMPACT LOADER

Automatic system for loading precious metal grains on T-Dosing

T-Compact Loader™ is an automated system designed for loading precious metal grains into the hoppers of the T-Dosing™ machine.

Its ability to efficiently manage separated production batches, the robustness of thestructure, and the reliability of the chain transmission mechanism make it an ideal tool for the precious metals industry. The inclusion of ergonomic and advanced safety features, such as laser barriers and removablecarriage containers, prioritize efficiency, operator well-being, and process safety.

T-CRYSTAL HOPPER

Dosage hopper for silver crystals

The T-Crystal Hopper is designed for the storage and transfer of silver crystals to the T-Lift High Special cup conveyor, which then discharges them into the crucible of a tilting furnace.

The operator sets the desired amount of crystals and starts the system: from that point on, the transfer process proceeds automatically and in sync. The crystals are smoothly conveyed to the T-Lift High Special, which transports and discharges them directly into the furnace crucible, ensuring precision and efficiency at every stage.

WHAT ARE GRAINS?

Grains are one of the many forms of precious metals and are the foundation for many types of processing.

Depending on the purity of the metal and the size of the grains, they are used in jewelry manufacturing, smelting, or for producing specific metal alloys.

Due to their small and regular morphology, grains are ideal for processes where precise dosing is required, such as the production of investment ingots.

Purity

- Gold: Gold grains used for investment ingots are characterized by high purity, often 99.99% (24 carats).

- Silver: The standard purity for silver is 99.9% or higher.

- Platinum and Palladium: These metals are typically refined to purities of 99.95% or higher.

Grains morphology

The grains must be small and regular, sized between XX and YY mm, and should be spherical or hemispherical to minimize air bubble formation.

Chemical composition and lack of oxidation

Grains must be free from contaminants, impurities, and surface oxides that could compromise the quality of the ingot.

Packaging and storage

Grains must be packaged under conditions that preserve their purity and quality, often in oxygen-free or vacuum environments, and in non-reactive containers.