Robot cells for the production of fashion accessories

The use of robotized cells for the tending of computer numerical control machines is a revolutionary system that has deeply affected the production potential of many Italian companies operating in the manufacturing of metal accessories for the fashion industry, i.e. accessories for clothing and/or bags/leather goods.

In order to reflect the world-wide renowned “Made in Italy” style, such items must be packaged in compliance with strict high-quality requirements and often in large batches. It is easy to achieve these two parameters through the use of automated robotic systems.

COMPETITIVE SMART FACTORIES

In the recent past, in the wake of work globalization, many Italian companies in this sector have decentralized their production sites abroad. Most of them were moved to emerging markets economies, in order to cope with the heavy production costs of their place of origin. However, this has turned out to be like a boomerang, since the price to pay was a drastic drop in the quality of the manufactured goods. Subsequently and understandably, buyers moved away/distanced from them.

Yet, in recent years, many entrepreneurs - farsighted and faithful to the tradition of quality that distinguishes Italians all over the world - have chosen to face the difficulties by focusing on automation. For example, they installed industrial robots to which they assigned the production of semi-finished products and accessories.

This choice has proven to be a winning one. These smart factories of the fourth industrial revolution are at the top of global competitiveness, since they are able to produce items with very high and consistent quality and to handle very large productions.

ROBOTS AND SECONDARY MACHINING PROCESSED ITEMS

Secondary machining is typical of the fashion accessories sector. So, let's see what it means to entrust its management to an automated system.

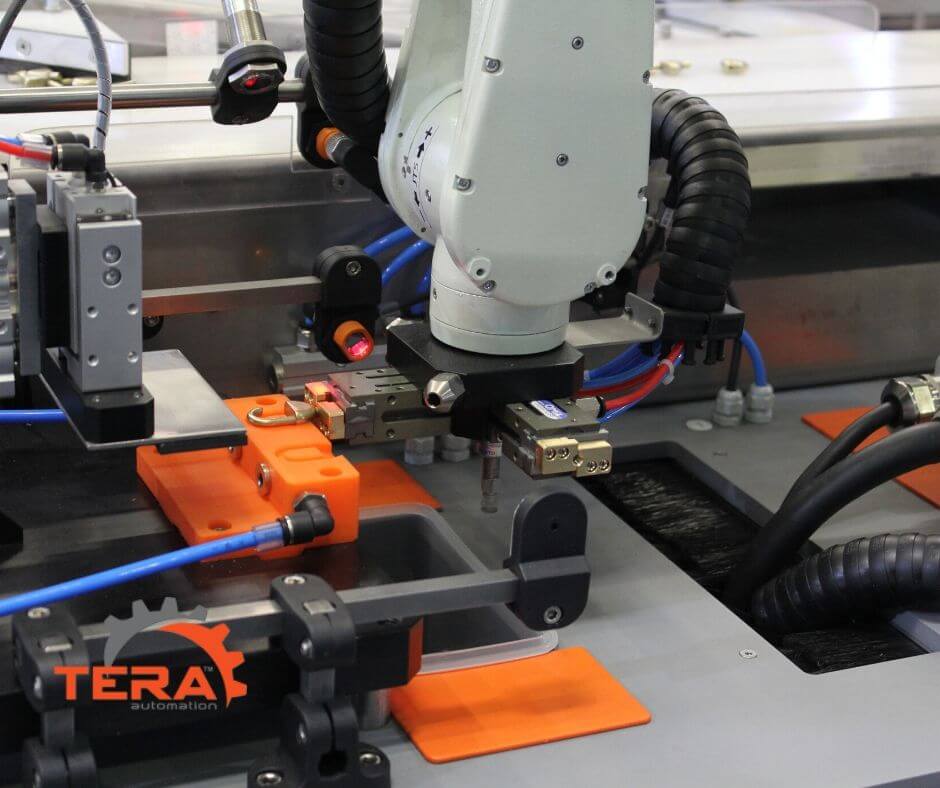

In a robotic cell, the raw workpieces are placed in the vise of the CNC machine by the robot. There they undergo the first phase of machining. Subsequently, the part is removed from the robotic arm, and positioned in the following vise inside the CNC machine. A second series of machining operations is performed (the secondary machining process).

Through the different phases (which vary according to the type of semi-finished product and to the CNC machine characteristics), it is possible to carry out all the necessary operations to complete the fashion accessory in a very short time and with very high, constant, repeatable quality standards.

HIGH FASHION, HIGH STANDARDS: AN HELP FROM INDUSTRIAL AUTOMATION

The production of fashion accessories for the luxury market represents a very particular segment in the production of semi-finished metal products. Fashion brands, in fact, select their suppliers based on very strict requirements and, with rare exceptions, do not make production programs available, not even for continuative ones. This very selective approach is proportional to the quality of the end-product, its durability and the brand perception in the market.

In this context, subcontractors involved in the production of small metal parts (and not only) for fashion are required:

- to manufacture large batches in short time;

- to be able to manage production peaks (as a result of changing trends);

- to follow very strict quality parameters;

- to be flexible when managing and producing new models (design).

This is a working scenario that is not simple at all, in which it is easy to understand the added value of the installation of a high-performance industrial automation such as a robotized cell for CNC machine tending.

In addition to performing an operator's work more quickly, the robot cell has no timetables and can run continuously for up to 96 hours and more. It has no drops in productivity and the results are always constant. Considering what we said earlier about the demanding requirements imposed by the fashion industry, it is even more evident that this is a winning solution for many professionals in this field.

But that's not all. In our experience, there are a number of technical measures that can, if possible, make the installed robotic solution even more productive and flexible. Let’s see some examples:

- the use of hoppers with variable volumes, in accordance with the required buffer;

- the use of dowel pins for the quick change of vises and therefore the possibility to switch from one format to another (also autonomously);

- the use of CNC machines with rotary table.

TOP QUALITY: THE WATCHWORD FOR THE FUTURE

Robotic cells represent the amazing present-day reality of many companies that produce fashion accessories. But just as many have not yet understood what it can mean to install a robotic cell in a company. Fear? Reluctance? In some cases, yes. And only popularization/awareness can make a difference.

However, for us who deal with industrial automation, the future is already today. At Tera Automation we work on our applications by equipping them with Artificial Intelligence devices, increasingly precise vision systems and remote management systems for troubleshooting with wearable "see-what-I-see" devices.

It is therefore easy to understand that the benefits of moving to automated fashion accessories production will be greater if technological innovation extends to everything related to quality control, in a complete production and management system that can maximize work.