FROM METAL MELTING TO THE PACKAGING OF INGOTS AND COINS

The minting process, or coinage, is the set of stages through which raw metal is transformed into high-quality coins or ingots. This process requires precision and care to achieve uniform and premium products. From metal melting to the creation of the final design, minting involves several operations, including rolling, blanking, and finishing. Each phase is essential to ensure that the final product meets high standards of purity, aesthetics, and commercial value.

SOLUTIONS FOR MINTING

T-ECOPRESS

Pneumo-hydraulic press for pressing and marking

T-Ecopress is an innovative pneumo-hydraulic press designed for pressing and marking, characterised by a C-shaped structure that provides easy access to the working area. Equipped with a touch-screen interface for intuitive management of operating parameters, this machine offers convenience, efficiency and safety. The upper and lower laser barriers, combined with the double-button manual start, ensure a safe working environment, while the absence of a hydraulic power unit reduces running costs and environmental impact.

T-SORTING

Automatic blank coins & bars weight check and sorting.

The 100% precise & accurate weight control in the production process is the only way to optimize the production. In addition, the weighing offers the possibility to divide the coins/blanks in weight classes and so prepare them for a possible material recovery. With T-Sorting, this delicate weighing and sorting process is automated, and the material is sorted into compliant, underweight or overweight.

The weighing process happens with a resolution of 1 mg and with a repeated precision of +/- 2mg. If the measurement shows that the product does not have the desired weight, it will automatically be displaced into the reject area and will not move on to the following production process.

T-ROBOMINT

Automated minting station

T-Robomint™ is an advanced automation system for refineries and mints, ideal for the continuous production of coins, medals and ingots in different formats.

Using Cartesian axis technology, it transforms manual presses into autonomous machines, reducing the need for direct supervision.

With a rapid change of moulds and components, it guarantees maximum flexibility, uninterrupted production shifts and constant output over time.

Innovative and efficient, T-Robomint™ revolutionises the stamping division.

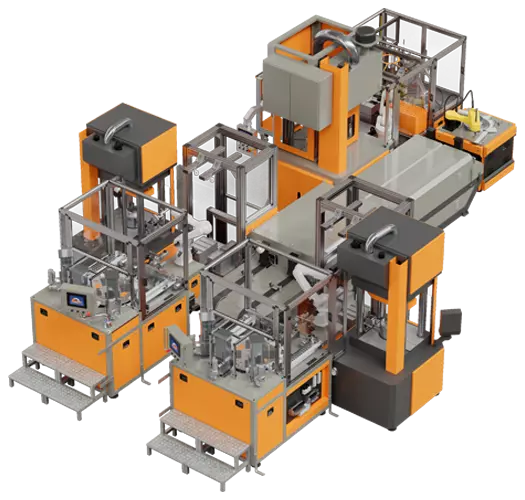

MINTING LINE

Complete line for minting coins and stamping bars

A complete line of machinery and accessories, carefully selected according to the type and quantity of products to be made.

T-SINTERMINT LINE

Automated line for the production of blanks and coins starting from precious metal powder

Thanks to an innovative sintering process, molten metal is atomized into powder and then transformed into the finished product, completely eliminating the use of sheets. Comprising 3 semi-manual phases and 6 fully automated phases, this technology revolutionizes the traditional production method, redefining every aspect of minting: from the technology employed to the investment in fixed capital. Compact, efficient, and sustainable, the T-Sintermint Line marks the beginning of a new era in coinage, ensuring unprecedented savings and quality.

THE 3 STAGES OF MINTING

Sheet production

Precious metal is melted and shaped into sheets. The process includes intermediate stages such as brushing, rolling, annealing, and shearing.

Blank production

The sheet is transformed into "blanks," or semi-finished products with the shape and size of the final product. This stage includes operations such as blanking, edging, weighing, finishing, and washing.

Coining

The blanks obtained in the previous stages are ready to be minted and brought to their final shape through the coining and packaging stages.