Why this furnace was a challenge

- Platinum and palladium tend not to release gases (such as oxygen and hydrogen) which are present on the grains/powder/scraps during the melting process. They retain it and cause the formation of macro-voids within the ingots, thus resulting in products with significant imperfections.

- The action of oxygen combined with high temperatures results in oxidation of the ingot molds which house the metallic material. Therefore, consumables deteriorate more and faster.

- In the past, melting these metals meant heating them with a blowtorch and then hammering or meshing the finished product into a single compact piece. As a result, a high level of ingot quality could not be achieved.

- The difficult repeatability of the results of the manual process should not be ignored either, since the outcome of this process, as in the past, is closely related to the sensitivity and experience of the operator.

How it is structured and how it works

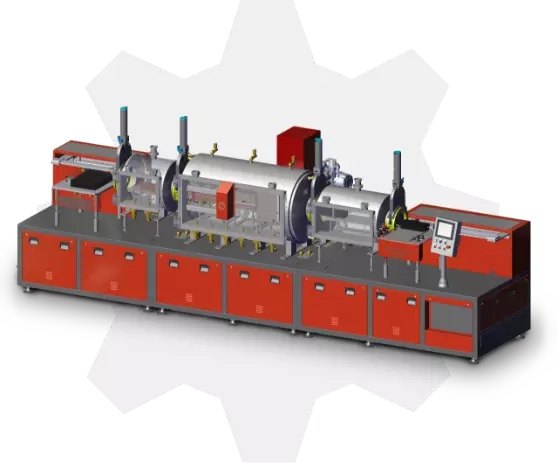

The furnace is composed as follows:

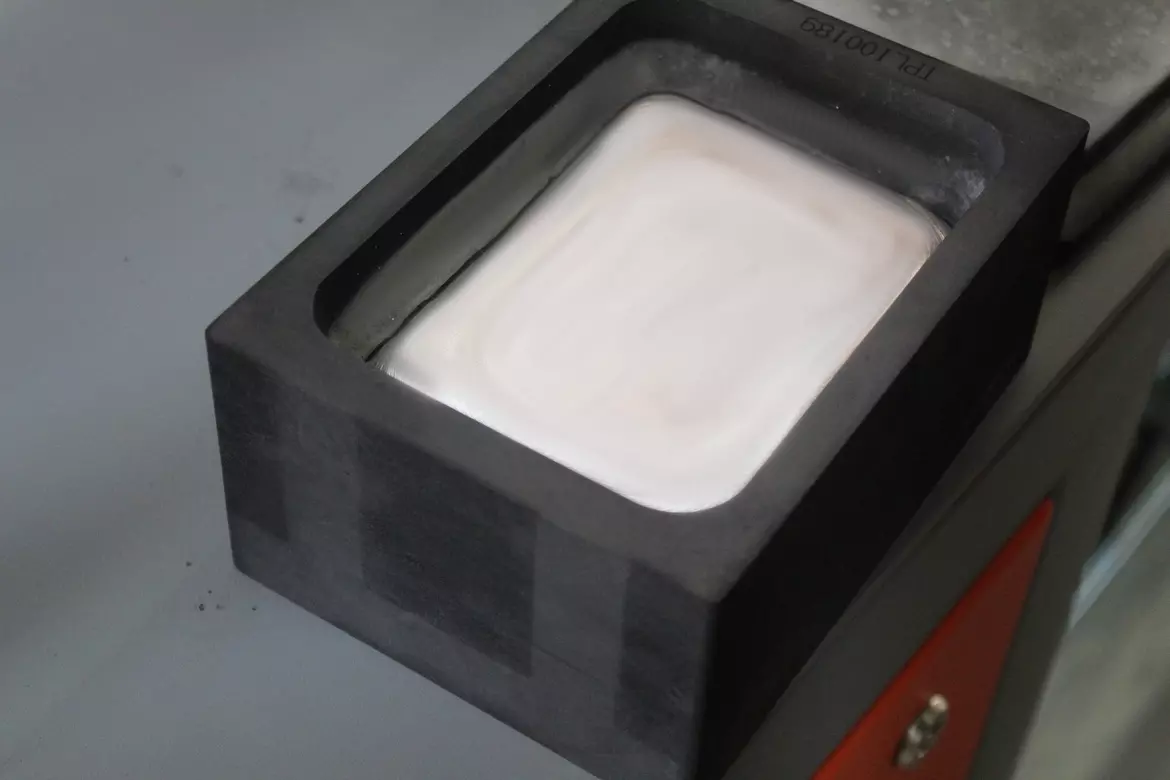

- Loading area: in this area, the ingot molds are manually placed by the operator. The ingot molds are then automatically pushed inside the tunnel furnace.

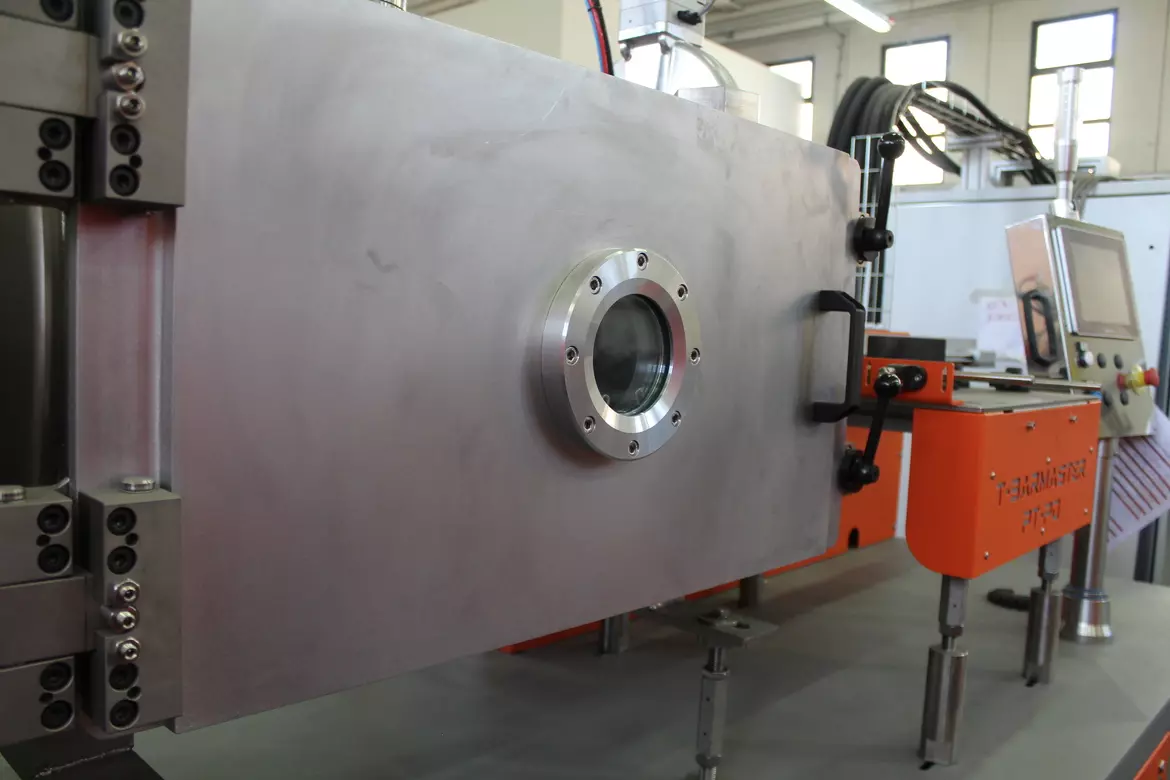

- Airlock (inlet): the previously manually loaded ingots are pushed into the first vacuum chamber. The chamber can vary its pressure from atmospheric pressure (when receiving material from outside) to high vacuum pressure (when it must move the metal forward into the melting area).

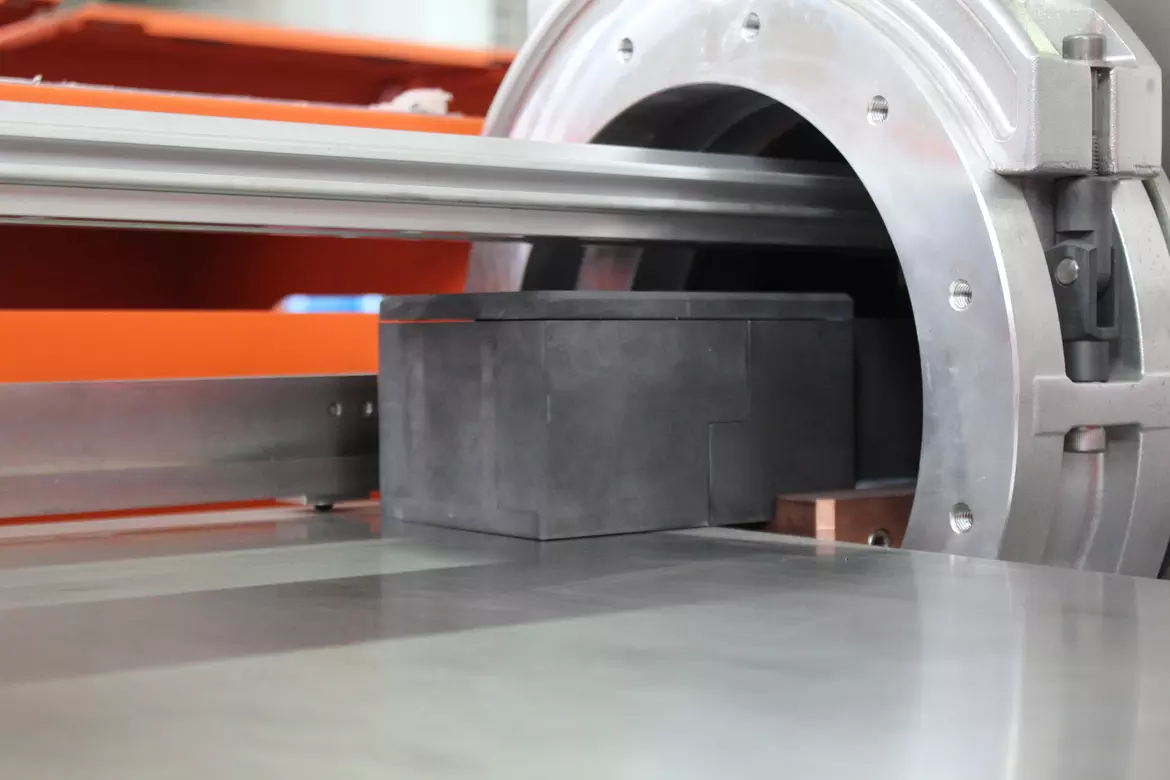

- Process chamber: Vacuum chamber where melting - solidification and cooling of the metal occur in sequence.

- Airlock (outlet): it operates in the same way as the inlet airlock, also contributes to the further cooling of the metal.

- Exit area: in this area, the operator can collect the ingot molds with the molten ingots inside. This section can stock a buffer of 5 ingot molds before the operator has to intervene manually to remove them.

Movements between the various areas take place by means of appropriate electrical and pneumatic drives.

Benefits of an automated solution for platinum and palladium melting

Automated production of platinum and palladium ingots

By means of the high vacuum realized in the vacuum chamber, the metal is melted and solidified in an area that is atmospherically isolated from the outside environment

The complete automation of the process allows the production of ingots by employing a minimum number of workers. Thanks to the systems provided, they operate under the best safety conditions

High quality of ingots and perfect product repeatability ensured by industrial mechanization

The use of readily available commercial resources and the use of common materials make this device economically competitive

CONTACT US

ASK FOR MORE INFORMATION

TERA AUTOMATION S.R.L.

Via Romena, 7/9 - Loc. Porrena

52014 Poppi (AR) - Italy

Phone: +39 0575536625

Fax: +39 0575539851

E-mail: tera@tera-automation.com

TERA WORLDWIDE

USA: New York

INDIA: Mumbai

TURKEY: Istanbul

THAILAND: Bangkok

SPAIN: Barcelona