T-FLEXIPACK

Robotic cell for palletizing items

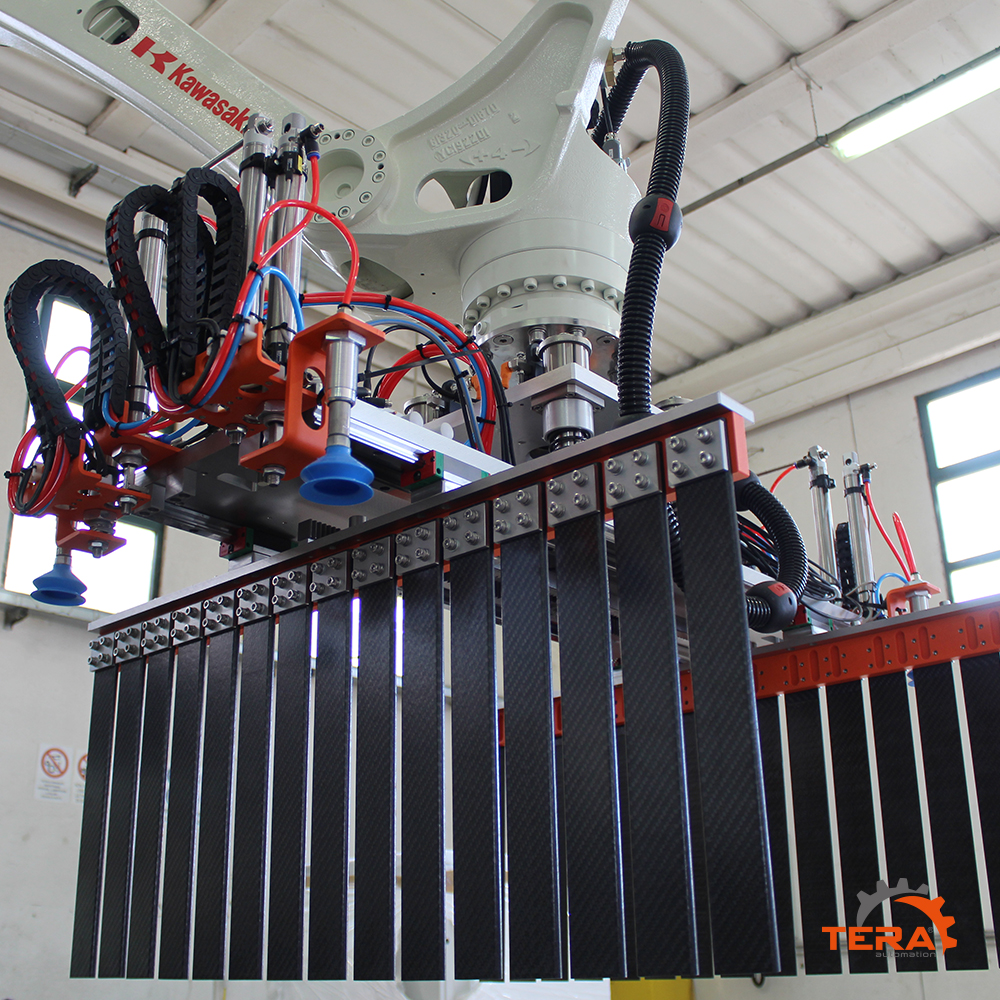

T-Flexipack™ is a robotic cell whose purpose is to carry out palletizing and depalletizing operations with items of different shapes and sizes.

The robotic cell can pick up and place objects to handle from and on:

- a conveyor belt

- a box/case

- a pallet.

That's why the most distinctive feature of the T-Flexipack™ robotic cells for palletizing is definitely their flexible application. This machine also takes its name from its flexible shape: its compact size is without any doubt a big advantage and, depending on the application type, it can change design according to the specific needs of the sector and the client.

T-FLEXIPACK CONSISTS OF:

- Structure supporting the robot;

- 2D vision system or loading station with centering and blocking system of the component;

- Palletizing station equipped with sensors to monitor the process;

- Anthropomorphic robot, SCARA or Cartesian robot with optional Industry 4.0;

- Single or multiple gripping system, depending on the type and quantity of objects;

- HMI with touch screen to manage and control the T-FlexipackTM;

- Electric panel board with electric equipment and CNC and robot connections.

ADVANTAGES

THE BENEFITS OF AN INNOVATIVE, AUTOMATED SOLUTION:

01

Efficiency

24-hour processing, lower production costs, repeatable results.

02

Flexibility

Adaptability to customer requirements and various formats, compact design.

03

Safety

No manned work required.