T-Line Compact, the Revolution in ingots production

In 2018 Tera Automation introduced to the world the first-ever T-Line, a groundbreaking solution for the automated production of precious metal ingots. A spark of intuition that changed the course of the industry, bringing it to an unprecedented level of automation, especially at the melting and finishing stages of ingot production.

Now, backed by years of experience, we’re proud to unveil T-Line Compact — the next step in a technology that’s always stayed one step ahead, anticipating market needs and delivering smarter, more modular, and more efficient solutions than ever before.

What is T-Line: the concept behind the line

T-Line is a fully automated line designed to transform precious metal powders or crystals into finished, packaged ingots — ready for sale.

The secret of its efficiency lies in two main features:

- Modularity: each component of the line is entirely designed and manufactured in-house by Tera Automation to ensure maximum integration and customization.

- Complete Automation: from granulation to marking, each phase is managed by interconnected robots and machines, according to the Industry 4.0 standards.

Over time, T-Line has made a name for itself as the ideal solution for silver ingot production, especially in case of large production volumes, when its full-size version becomes particularly convenient.

Why T-Line Compact: new demands, new solutions

As production requirements evolved – especially in the gold sector – a growing demand emerged for more compact and versatile automated solutions that are also capable of handling small batches efficiently.

This is where T-Line Compact takes shape: a line that retains the major advantages of the former version while incorporating important innovations aligned with market demands.

Key Innovations of T-Line Compact

- Overall footprint reduced by approximately 77%.

The most visible difference from the traditional T-Line is its compact size: T-Line Compact occupies only 38 m², compared to around 168 m² for the full-size version. This was made possible by reducing the number of processing steps from six to four, eliminating the preliminary phase of melting and granule treatment, and starting instead from perfectly dry granules.

- New purpose-designed modules

To enhance both performance and compactness, Tera Automation developed brand-new modules such as the T-Barmaster Powerloop and T-Compact Loader, designed specifically to integrate seamlessly into the new compact layout.

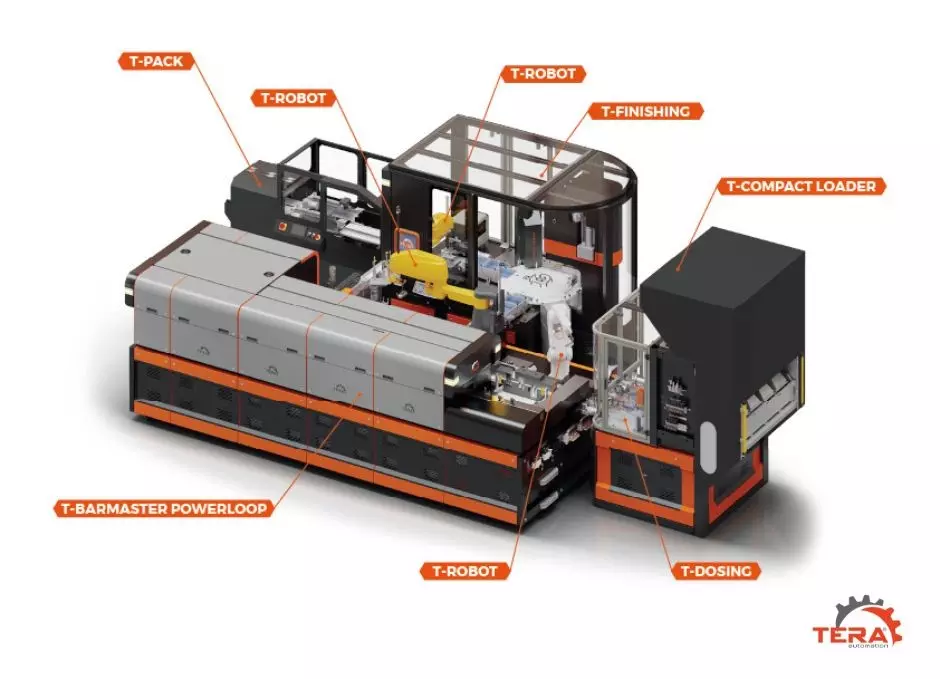

The modules that make up the line

T-Line Compact is made up of a series of technologically advanced modules, each serving a specific function in the production cycle. Integrating these elements guarantees a continuous, efficient and fully automated workflow.

- T-Compact Loader: automatic granule loading system

- T-Dosing 4H: high-precision automatic dosing system

- T-Robot: anthropomorphic robot for granule transfer and mold lid handling

- T-Barmaster Powerloop 160kW: tunnel induction furnace for melting and solidifying bullion from 1 oz to 400 oz

- T-Robot Scara handles bullion extraction, weight verification, and transfer to finishing

- T-Finishing Line: automatic line for marking, serial numbering, and quality control

- T-Pack: machine for shrink wrapping ingots.

Innovations at the core of T-Line Compact

The thermal heart of the line is T-Barmaster Powerloop, a U-shaped tunnel furnace which allows a continuous and perfectly controlled melting process in a protected atmosphere.

Its key innovation compared to the previous version is its loop layout, which integrates two internal mold handling systems (conveyor belts and chains) directly within the structure, eliminating the need for external modules. It is engineered for continuous-cycle production, delivering high throughput with minimal space requirements.

To improve the automatic loading of granules, Tera Automation has developed the T-Compact Loader: a compact, highly efficient system that perfectly integrates with the T-Dosing module.

With this device, the operator simply places the granule trays on an ergonomic loading platform and starts the process. A conveyor chain automatically lifts and empties the trays into the T-Dosing hoppers, ensuring a continuous flow with no manual effort.

As it was specifically designed to work in synergy with T-Dosing, the system also significantly reduces the space typically occupied by traditional bucket conveyors like the T-Lift.

A strategic investment for refineries and mints

With a production capacity of up to 500 ingots per hour, T-Line Compact represents a qualitative leap for companies involved in the melting, refining, and commercialization of precious metals.

Its high level of automation allows for:

- reduced operational costs

- optimized personnel usage

- standardized product quality

ensuring extremely competitive return-on-investment times.

T-Line Compact is our answer to a constantly evolving market. Compact, intelligent, and flexible, it brings together all of Tera Automation’s expertise into a solution capable of adapting to the needs of precious metal producers—today and in the future.