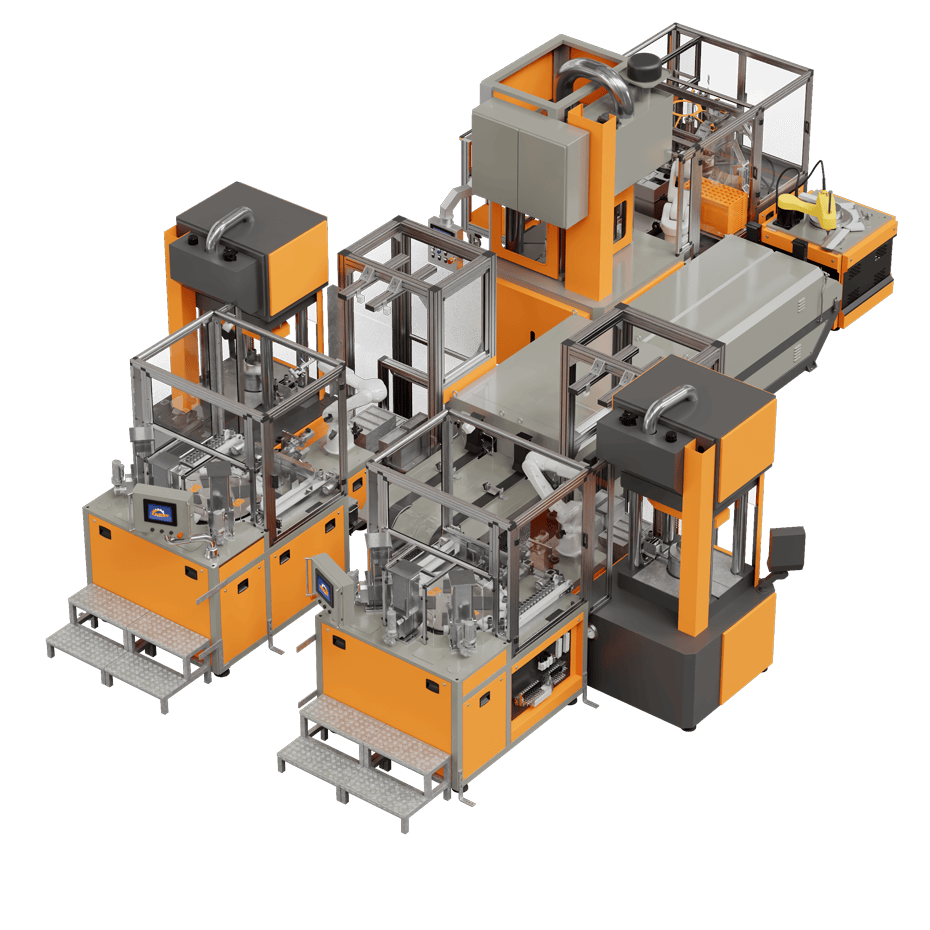

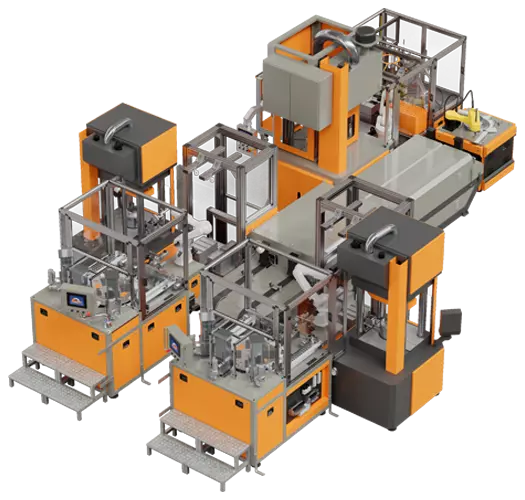

T-SINTERMINT LINE

Automated line for the production of blanks and coins starting from precious metal powder

Thanks to an innovative sintering process, molten metal is atomized into powder and then transformed into the finished product, completely eliminating the use of sheets. Comprising 3 semi-manual phases and 6 fully automated phases, this technology revolutionizes the traditional production method, redefining every aspect of minting: from the technology employed to the investment in fixed capital. Compact, efficient, and sustainable, the T-Sintermint Line marks the beginning of a new era in coinage, ensuring unprecedented savings and quality.

THE PROCESS

1

Atomization

of molten metal using high-pressure water jets

2

Drying

of the metal powder

3

Sieving

to select optimal grain size

4

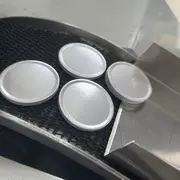

Powder dosing

in single-dose cups

5

Pressing

the powder into blanks

6

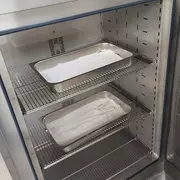

Thermal sintering

of blanks

7

Edge rimming

for coins

8

Coining

in high proof quality

ADVANTAGES

8 GREAT ADVANTAGES

110.000 blanks/month, about 1,5/2 mln blanks/year.

Only 115–120 kg of raw material needed to produce 100 kg of coins.

Scrap reduced to 15–20%, versus 67% in conventional methods.

Compact size: just 48 m² for a complete system.

Only 6 production stages, compared to 11 in the traditional process, which means fewer machines and fewer workers.

4 out of 6 processes are fully automated.

Customisable to production requirements.

Superior quality: high-proof finish levels can be achieved thanks to the higher impressionability of sintered powder.