Tera's New Technologies for Good Delivery Bar Production

Over the past year, Tera Automation has ramped up innovation, developing solutions that meet the growing demands of the Good Delivery bar market.

The goal has been to enhance not only the furnaces but also accessories and integrated systems, providing our clients with fully automated and highly efficient solutions.

Efficiency, Space, and Quality

Tera Automation's new technologies address the most critical challenges in the industry, offering solutions that:

- Reduce resource consumption

- Minimize footprint

- Optimize the entire production cycle

- Ensure high performance and improve final quality

T-Barmaster 1000 Spaceless: Efficiency and Innovation

One year ago, we launched the T-Barmaster Spaceless, the first induction tunnel furnace without spacers designed for producing bars from 1 ounce to 5 kg. After a year of excellent feedback, we expanded the range with the T-Barmaster 400 Spaceless and T-Barmaster 1000 Spaceless, capable of producing bars up to 1000 oz.

The T-Barmaster 1000 Spaceless is an integrated system that transforms granules into high-quality Good Delivery bars through a fully automated and continuous process.

The main advantages of this solution include:

- Reduced Footprint: The "U" configuration makes the furnace more compact than traditional furnaces.

- High Productivity: A 100 kW furnace can produce 7-8 bars per hour, with an efficiency of 2,4 kg of metal produced per kW absorbed.

- Graphite Savings: The removal of spacers and ingot molds covers reduces graphite use by 81%.

To ensure a continuous production flow, the T-Barmaster 1000 Spaceless can be integrated with several other advanced modules, including the T-Hopper, T-Doselift, and T-WM, which manage the dosing, handling of granules, weighing and serialization of Good Delivery bars.

IT-Onecast: The Complete Solution for Direct Melting

The IT-Onecast was developed to address an increasing demand from our clients: to produce Good Delivery bars directly from refined precious metal crystals, bypassing the intermediate stage of granule melting.

Thanks to advanced engineering, Tera Automation has developed the only machine in the world capable of producing Good Delivery bars in a single production cycle, directly from refined metal, saving both time and resources.

The system consists of two main sections:

- A tilting induction furnace for melting the refined metal

- The T-Barmaster 1000 Spaceless with a load cell, which completes the production cycle with dosing, homogenization, solidification, and cooling of the bars.

The Complete Production Cycle

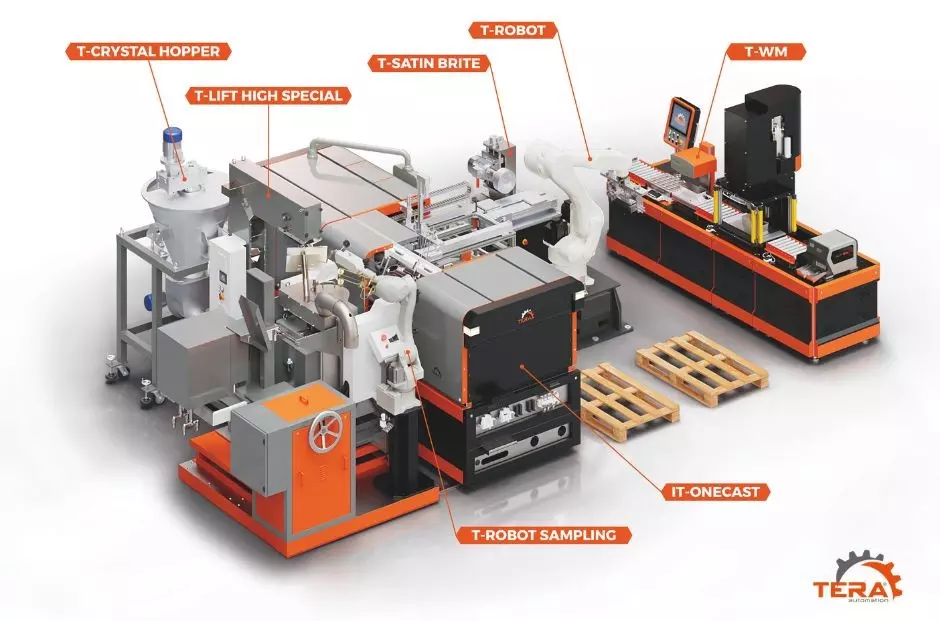

To complete the IT-Onecast and turn it into an “end-to-end” solution, Tera Automation has designed a line that integrates all the necessary steps for producing serialized and palletized Good Delivery bars.

This line includes:

- T-Crystal Hopper: dosing hopper for silver crystals, designed to feed the T-Lift High Special.

- T-Lift High Special: bucket conveyor belt to transfer the metals from the hopper to the discharge point.

- T-Robot Sampling: anthropomorphic robot for molten metal sampling.

- T-Robopallet: for bar handling, equipped with an integrated camera for quality control.

- T-Satin Brite: a machine for satin finishing bars, improving productivity with simultaneous loading/unloading.

- T-WM Plus: an integrated system for weighing and marking bars in compliance with LBMA standards.

T-WM: Precision and Traceability for Good Delivery Bars

The T-WM (Weight & Mark) is the integrated system for weighing and marking Good Delivery bars in gold and silver.

Designed to ensure absolute precision, complete traceability, and operational ergonomics, this machine integrates perfectly with both the IT-Onecast furnace and the T-Barmaster 1000 Spaceless.

As a machine dedicated to Good Delivery bar processing, we’ve equipped it with the Sartorius GBB14202S-0CE electronic scale, the first approved by the LBMA according to the Good Delivery Rules.

With a weighing range of up to 14.2 kg and a reading accuracy of 0.01 g, it provides reliable measurements that comply with international standards, making it the ideal tool for managing Good Delivery bars in gold and silver.

Main Funcitons of the T-WM

- High-precision weighing in compliance with LBMA standards for Good Delivery bars

- Direct micro-percussion marking, preserving the metal without removal

- Ergonomic handling of weighing and marking, with facilitated movement and an intuitive interface

Advantages of the New Version

-

- Advanced Connectivity:

- Software designed for integrating LBMA-required data

- Compatibility with the digital platform based on DLT/GBI technology (Gold Bar Integrity Ecosystem)

- Direct connection with the company’s ERP system

- Complete Traceability:

- Storage of legal weight, serial number, date, and time

- Scalability and Automation:

- Option to convert the unit into a fully automated station

- Integration with handling robot

- Direct connection to production lines with T-Barmaster furnaces, T-Barmaster Spaceless, and the IT-Onecast system.

With the new version of the T-WM, Tera Automation not only guarantees precision and compliance with LBMA standards but also offers a solution ready for the future of international digital traceability of gold and silver, in line with the latest production technologies and LBMA’s global initiatives.

Tera Automation Machinery: The Complete Solution for Good Delivery Bar Production

The innovations introduced by Tera Automation – from the T-Barmaster 1000 Spaceless to IT-Onecast and the T-WM system – provide refineries with an ecosystem of integrated, scalable, and fully automated solutions for producing Good Delivery bars.

Reduced footprint, energy efficiency, and guaranteed quality at every stage of the process allow precious metals companies to remain competitive in an increasingly demanding market that prioritizes resource optimization and transparency throughout the supply chain.