T-Sintermint Line: The New Frontier in Minting Production

At the prestigious 49th IPMI Annual Conference, we had the pleasure of presenting an automation technology that we confidently describe as "disruptive": the T-Sintermint Line.

Born from the collaboration between ABC Bullion and the Italian company Coinatec, this new process is set to radically transform the minting industry, thanks to a completely new approach based on metal powder sintering.

Historical Evolution of Minting Technology

Coin production has undergone significant technological advancements over time.

Some of the most notable include:

- In 1790, the introduction of industrial rolling mills enabled the production of uniform metal sheets.

- In 1850, the first automatic mechanical presses were introduced.

- In the early 1900s, annealing furnaces came into widespread use.

- Since the 1950s high-tonnage hydraulic presses have become widespread, capable of operating with higher precision and at greater speed.

Yet despite centuries of innovation, minting had never experienced a truly automated revolution. Each phase remained isolated, carried out by separate machines and human operators—until now.

The Limitations of the Traditional Process

The classical minting process remains highly segmented and manual. It starts with a metal sheet produced by melting and rolling, followed by cutting, annealing, blanking, edge rimming, and finally coining—resulting in 11 separate stages involving 10 different machines.

In addition to its complexity, this method requires constant operator supervision and produces a considerable amount of scrap (up to 67% of the processed metal).

T-Sintermint: A New Production Paradigm

With T-Sintermint technology, metal sheets are eliminated. The molten metal is atomized into powder, which becomes the raw material for a high-precision sintering process.

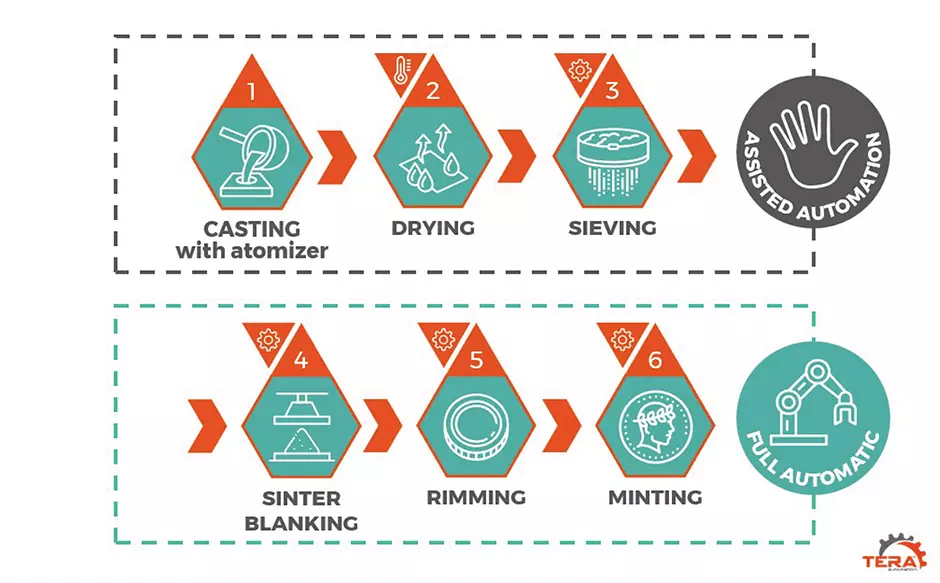

The main stages of the new process

- Atomization of molten metal using high-pressure water jets

- Drying of the metal powder

- Sieving to select optimal grain size

- Fully automated mechanical and thermal sintering

- Optional edge rimming for coins

- Final inline automatic coining.

Full Automation with Micrometric Process Control

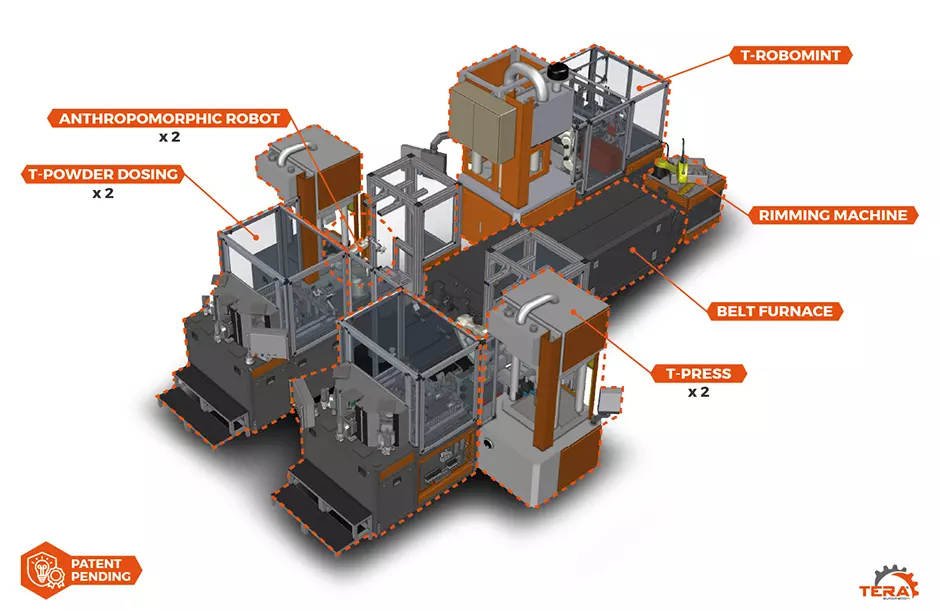

At the heart of the T-Sintermint Line is a high-precision robotic system.

Here’s how it works:

- Micrometric doses of powder are weighed using high-precision systems and loaded into containers

- A first anthropomorphic robot moves the containers to the compaction presses

- The presses compact the powder to form blanks

- Blanks are sintered in a dedicated conveyor belt furnace

- A second anthropomorphic robot places the sintered blanks into the rimming station

- A third robot handles the blanks for final coining, checks final weight, and initiates palletization.

All of these steps are performed without human intervention.

What Are the Production Advantages?

- Continuous, high-efficiency production: 6 to 8 pieces per minute, with an annual capacity of around 2 million coins

- 24/7 operational capability, even without operator presence

- Just 6 production steps, compared to the 11 in the traditional process

- Reduced production time: less than 10 minutes per coin

- Scrap reduced to 15–20%, versus 67% in conventional methods

- Material savings: only 115–120 kg of raw material needed to produce 100 kg of coins

- Superior quality: high-proof finish levels can be achieved thanks to the higher impressionability of sintered powder.

- Compact size: just 48 m² for a complete system.

Conclusion

With the T-Sintermint Line, the entire minting production process has been completely revolutionized, addressing every component—from the technology employed to the capital investment in fixed assets.

This transformation represents a true example of Business Process Reengineering (BPR) applied to the minting industry.

The T-Sintermint Line marks the beginning of a new era in coin production: a compact, automated, efficient, and sustainable system capable of delivering exceptionally high-quality results.

Thanks to this innovative approach, waste is reduced, the quality of the finished product is significantly improved, and a new standard of excellence is established in the minting process.