THE SMALLEST INDUCTION TUNNEL FURNACE EVER CREATED. MORE COMPACT,

BETTER PERFORMING

AND MORE ECO-FRIENDLY.

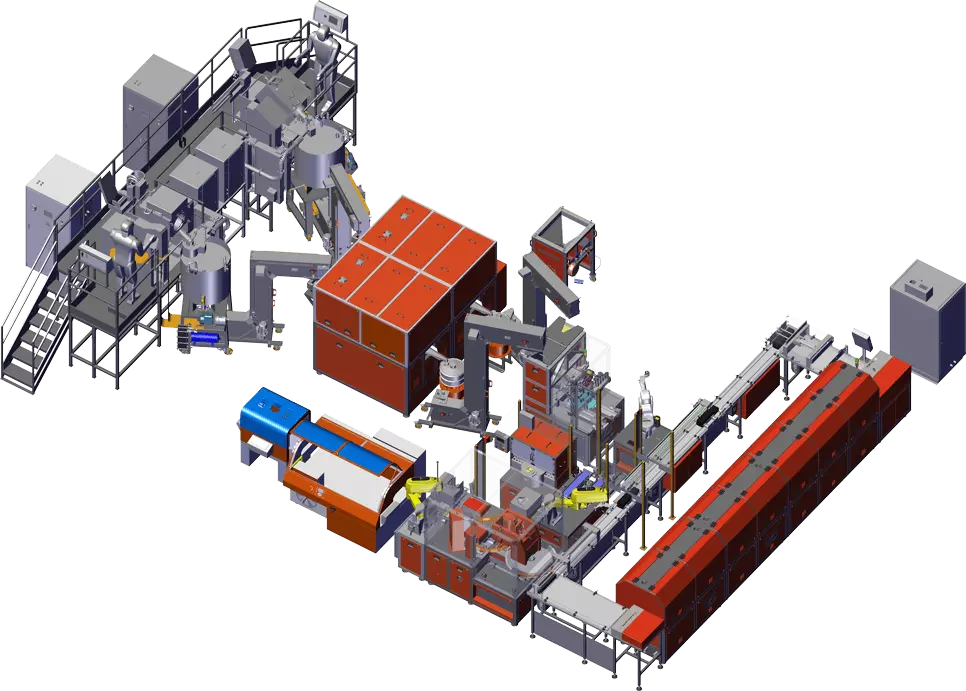

T-BARMASTER ONE SMART SPACELESS

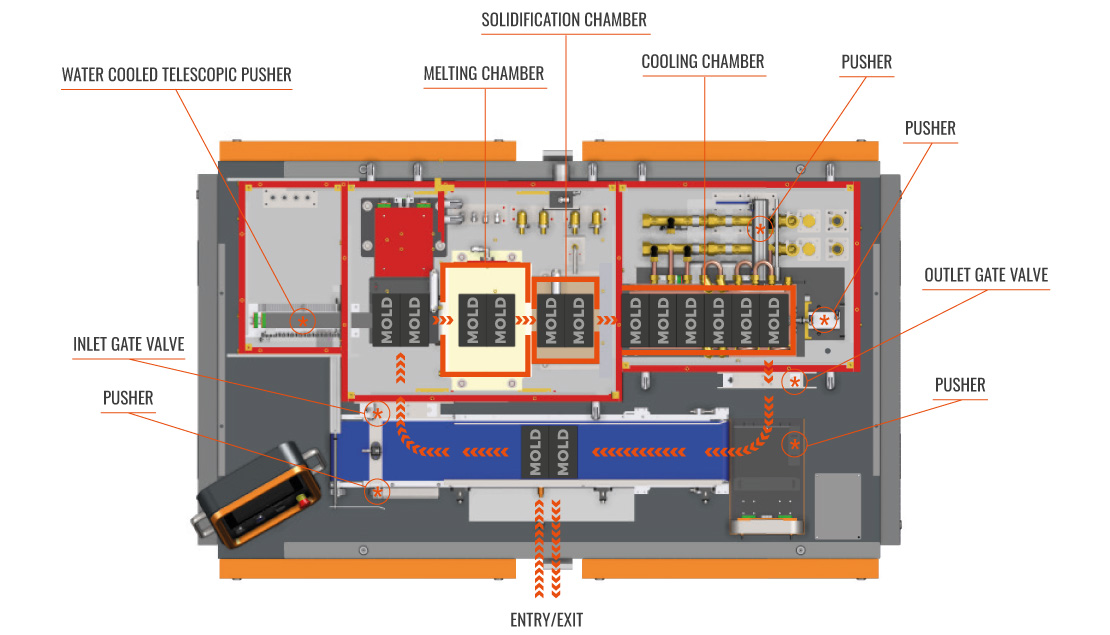

THE SPACELESS CONCEPT: NO MORE SPACER

Each Tera tunnel furnace - T-Barmaster - involves the use of ingot molds combined with spacers. Infact, spacer ensures perfect heat distribution in the ingot mold during melting.

But, why not design a tunnel furnace without spacers?

The "Spaceless" concept is geared towards maximum optimisation of our tunnel furnace. Less space occupied, less consumption, optimum performance. To achieve this, we decided to eliminate spacers and rethink the entire design of our T-Barmaster.

Overall dimensions (LxWxH): 2400 x 1350 x 1700 mm

Overall weight: 1500 kg

Converter on-board

Converter weight: included in the weight of the machine

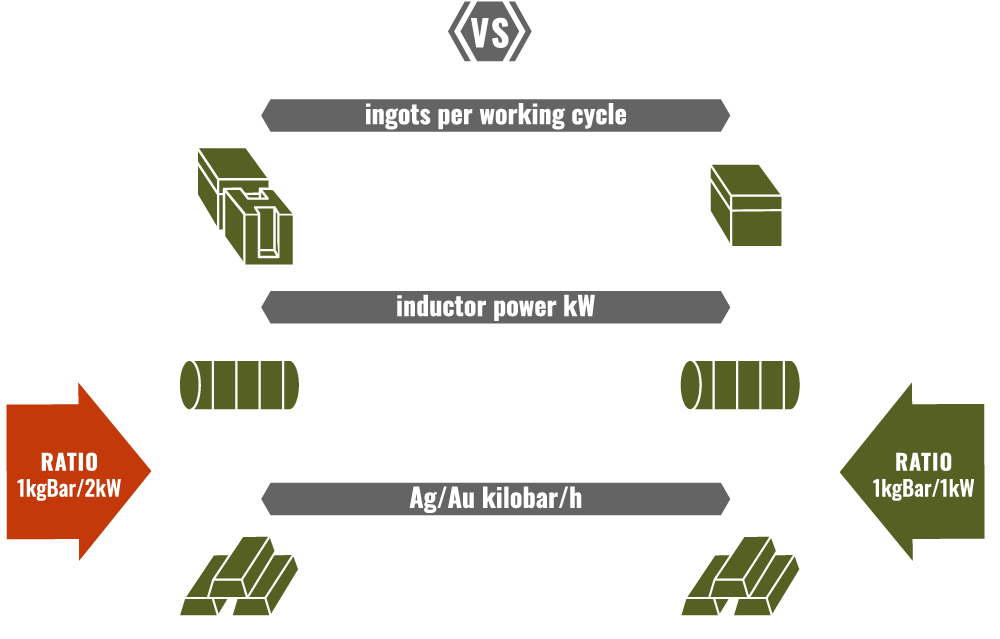

A NEW ECOLOGICAL APPROACH TO INGOTS PRODUCTION

Everyone wants high performance at a fair price, but eliminating spacers was also a choice of responsibility and awareness towards a more rational, conscious and ecological production.

With "Spaceless" furnaces, we have reduced footprint, raw material consumption and increased the consumption/production ratio: this translates into an advantage on all sides!

TECHNICAL DATA

- Total absorbed power: 24 kW

- Converter power: 20 kW

- Supply voltage: 400V - 3Ph-E - 50 Hz

- Cooling device: T-Chiller 081

- Air compressor: SX6

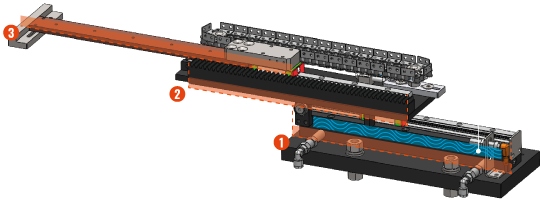

3 TECHNOLOGIES

THAT MAKE IT POSSIBLE

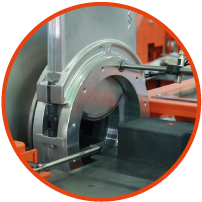

1 - WATER-COOLED TELESCOPIC PUSHER

Pusher with 3 thrust levels, driven by electric motor and with water-cooled base. Electronics and motor are located outside the range of the pusher in a protected environment.

2 - GATE VALVE...

...instead Pich Valve. Compared to our classic furnaces, in this case there is not one long train of molds but several trains of 2 molds respectively.

3 - HIGH-EFFICIENCY CONVERTER

Thanks to our collaboration with Italimpianti Orafi, we have developed internally a high-efficiency converter that is silent, compact and has an excellent power consumption ratio.

Max. power: 20 kW

Frequency: 45 - 50 kHz

Working point: auto-tuning

Noise level: < 30 dB

Dimensions WxHxD: 19.5 x 42.5 x 30 cm

Weight: 35 kg

HIGHER-QUALITY

GOLD AND SILVER INGOTS

WITH TERA AUTOMATION'S ACCESSORY EQUIPMENT

T-Nitro™

Pure nitrogen gas generator

T-Nitro, specifically designed for the Tunnel Furnace electromagnetic fields, guarantees a continuous production of pure nitrogen (up to 99,999%) of top quality, perfectly filtered and dehydrated.

T-Chiller

Cooling system

The critical phase of precious metals bars solidification must be fully controlled, T-Chiller ensures a constant flow of chilled water.

CUSTOMER CARE

FULL, IMMEDIATE SUPPORT WITHOUT BORDERS

A support service can be deemed efficient, only if it does not require halting production for long periods of time, wherever the customers might be in the world.

Our support team can be reached via direct call, remotely or with maintenance contracts. That means saving time and money.

Constant availability of spare parts

Our support service is particularly efficient, because we provide spare parts which are manufactured even with our own CNC machine, our warehouse is fully stocked with the most important spare parts and we guarantee a fast delivery.

Along with the T-Barmaster™ tunnel furnaces, we provide an original Tera Automation spare parts package, so as to ensure that the furnace always operates at full potential. Keeping a stock of the main spare parts is absolutely essential to guarantee production continuity and carry out simple maintenance tasks in an effective and timely manner. Our support team will create the spare parts package most suitable for your needs.

Consumables – Very high-quality ingot molds

Our very high-quality isostatic graphite ingot molds are designed to optimize our furnaces' performances. Since they have a longer average lifespan, operating costs are drastically reduced. Thanks to our great knowledge of casting processes and the constant search for the most adapted raw materials, we are always able to offer the best combination between different graphite types.

We work with a high-quality graphite supplier to provide our customers with different types of graphite at competitive prices.

CONTACT US

ASK FOR MORE INFORMATION

TERA AUTOMATION S.R.L.

Via Romena, 7/9 - Loc. Porrena

52014 Poppi (AR) - Italy

Phone: +39 0575536625

Fax: +39 0575539851

E-mail: tera@tera-automation.com

TERA WORLDWIDE

USA: New York

INDIA: Mumbai

TURKEY: Istanbul

THAILAND: Bangkok

SPAIN: Barcelona