AUTOMATIC INGOT CASTING MACHINETO PRODUCE PRECIOUS AND NON-FERROUS METAL ANODES AND BARS

T-CONVEYOR CAST™

INGOT CASTING MACHINE SUITABLE FOR INTEGRATION INTO ANY MELTING FURNACE

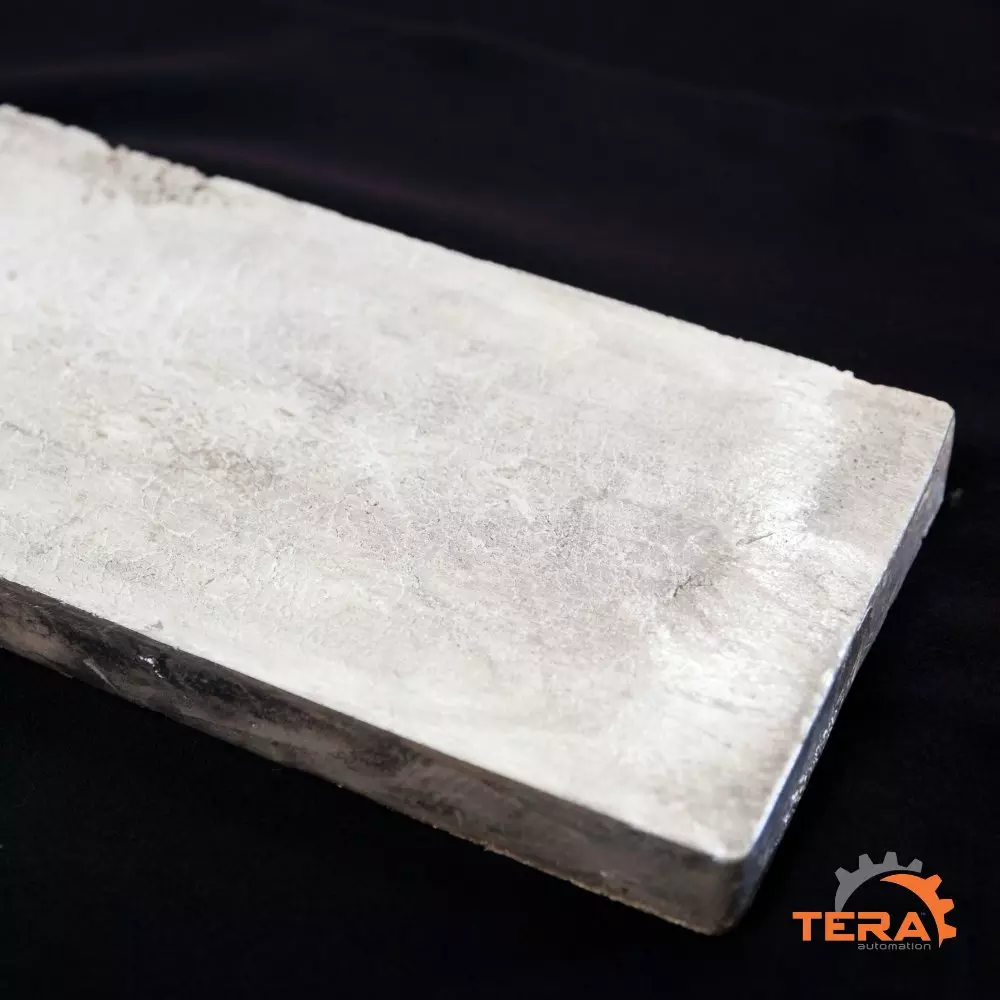

T-Conveyor Cast™ is a system designed for companies casting anodes and bars in precious and non-precious metal. As a matter of fact, this ingot casting machine can be combined to tilting melting furnaces with both vertical and horizontal casting, working with different types of molten metal: gold, silver, copper, brass, zinc, aluminum, etc.

We designed it specifically to lighten the burden of operators' manual workload - just think of the heavy weight of cast iron ingot molds alone - and to drastically reduce risks at work due to the proximity to furnaces. This is made possible by using a pushbutton panel (also available in a wireless version), which allows operating tasks at a safe distance.

Once you add the T-Conveyor Cast™ to your company's production flow, you will immediately perceive how much the pace of production of anodes and bars increases.

T-CONVEYOR CAST™

IS AVAILABLE AS:

THE PAST

CRITICAL ISSUES AND DISADVANTAGES OF THE TRADITIONAL SYSTEM

- During this step, operators must always work next to tilting furnaces

- Operators are continuously exposed to high temperatures and electromagnetic fields

- Strenuous and very dangerous manual operations

- Operators need a long time to carry out tasks, due to the weight of anodes and ingots

THE INNOVATION

THE ADVANTAGES OF THE T-CONVEYOR CAST™ INGOT CASTING MACHINE

- Operators simply have to load the metal in the crucible of the tilting furnace

- Management and control of all operations from a safe distance

- Minimum physical effort and no risks of burn for operators

- High-volume manufacturing in short periods of time

INGOT CASTING MACHINE FOR HIGH-VOLUME MANUFACTURING

T-Conveyor Cast Standard™For anodes and bars of different shapes

T-Conveyor Cast Standard™

THE MACHINE IN A NUTSHELL:

- It can be combined to any tilting melting furnace

- It produces anodes and bars of different shapes and in different metals, such as gold, silver, copper, brass, zinc, aluminum, etc.

- Monitoring from a safe distance

- Optimization of production time

- Cost optimization

- Eco-friendly machine

- Customizable

T-Conveyor Cast XL™For anodes and bars of different shapes

T-Conveyor Cast XL™

Twice the productivity of the Standard model

THE MACHINE IN A NUTSHELL:

- It can be combined to any tilting melting furnace

- It produces anodes and bars of different shapes and in different metals, such as gold, silver, copper, brass, zinc, aluminum, etc.

- Monitoring from a safe distance

- Optimization of production time

- Cost optimization

- Eco-friendly machine

- Customizable

HOW DOES

THE T-CONVEYOR CAST™ INGOT CASTING MACHINE WORK?

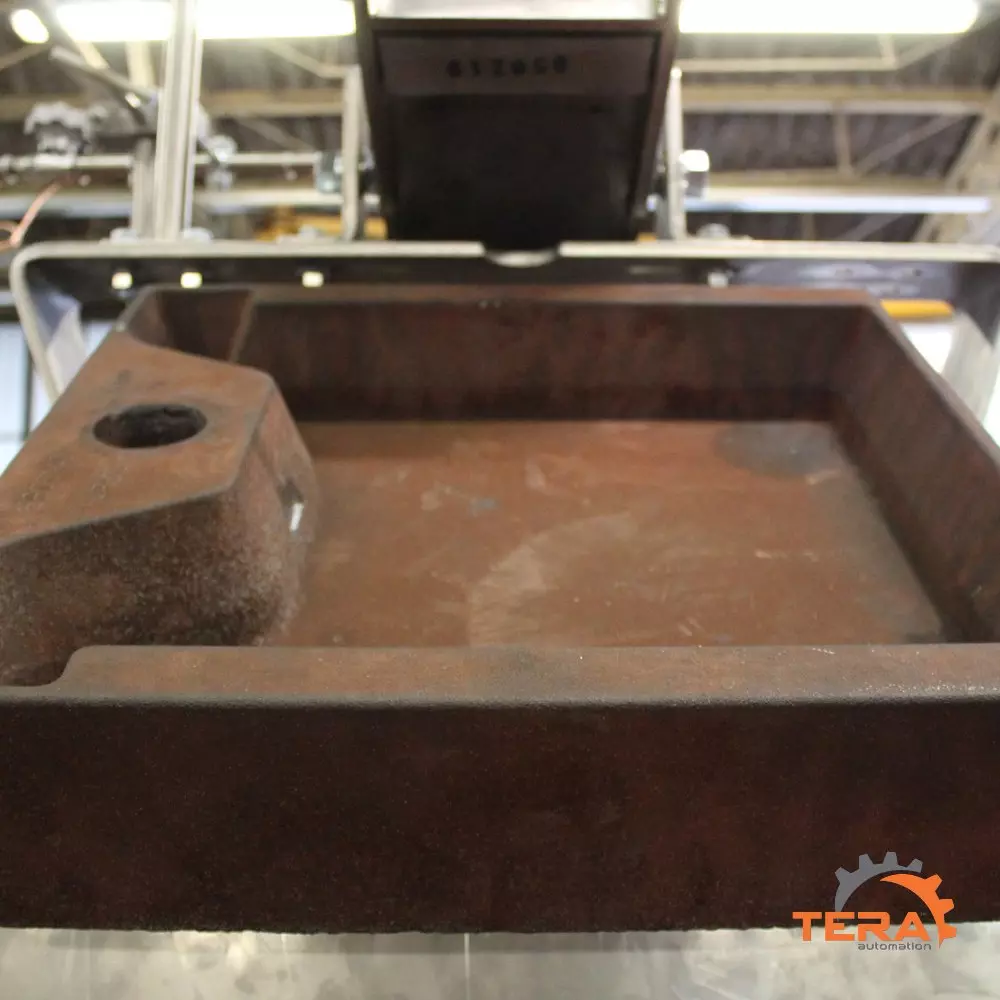

The T-Conveyor Cast™ ingot casting trolley is equipped with a remote control system to safely manage both the machine and the ingot molds: as a matter of fact, by using the pushbutton panel (also available in a wireless version), it is possible to move the T-Conveyor Cast™ in front of the tilting furnace and adjust it to the height of the casting level.

Furthermore, the machine can house many ingot molds of different shapes according to production needs: anodes, bars, ingots, etc.

TERA AUTOMATION'S

ORIGINAL ACCESSORIES

- Pre-heating ingot molds

- Bigger wheels and steering wheel for simpler movements

- Trolley tank to collect products

- Wireless remote control

- Pyrometer to self-adjust the temperature

- Automatic striker

CUSTOMER CARE

FULL, IMMEDIATE SUPPORT WITHOUT BORDERS

A support service can be deemed efficient, only if it does not require halting production for long periods of time, wherever the customers might be in the world.

Our support team can be reached via direct call, remotely or with maintenance contracts. That means saving time and money.

Constant availability of spare parts

Our support service is particularly efficient, because we provide spare parts which are manufactured even with our own CNC machine, our warehouse is fully stocked with the most important spare parts and we guarantee a fast delivery.

Along with the T-Conveyor Cast™ ingot casting machine, we provide an original Tera Automation spare parts package, so as to ensure that the machine always operates at full potential. Keeping a stock of the main spare parts is absolutely essential to guarantee production continuity and carry out simple maintenance tasks in an effective and timely manner. Our support team will create the spare parts package most suitable for your needs.

CONTACT US

ASK FOR MORE INFORMATION

TERA AUTOMATION S.R.L.

Via Romena, 7/9 - Loc. Porrena

52014 Poppi (AR) - Italy

Phone: +39 0575536625

Fax: +39 0575539851

E-mail: tera@tera-automation.com

TERA WORLDWIDE

USA: New York

INDIA: Mumbai

TURKEY: Istanbul

THAILAND: Bangkok

SPAIN: Barcelona